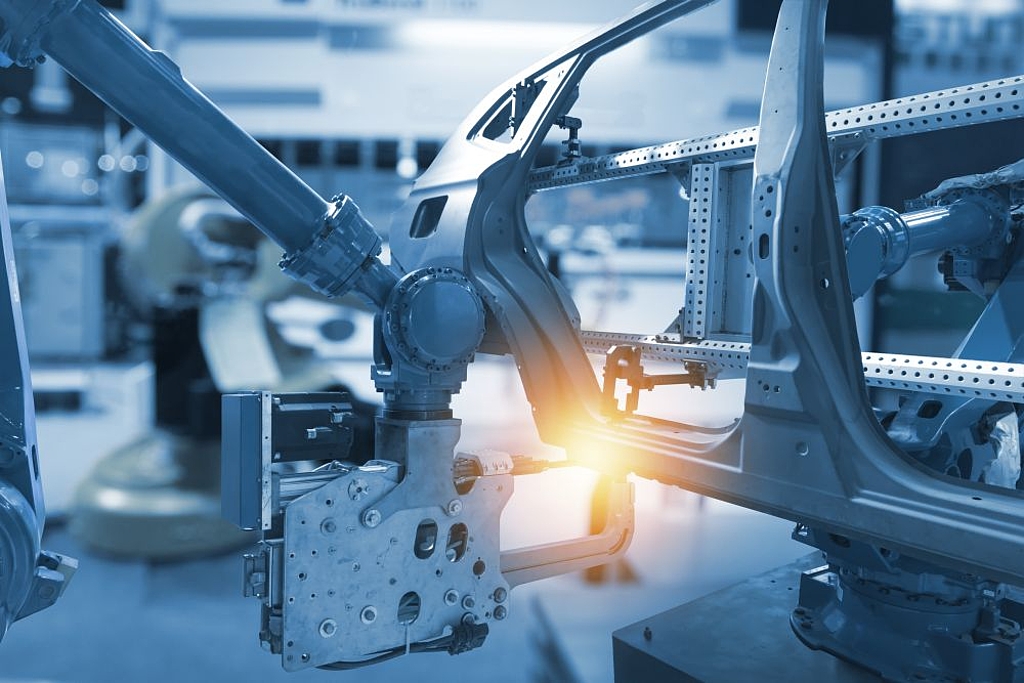

Comprehensive Logistics for Production of 88,000 Vehicles per Year

- Success Stories

Minth Group is a leading manufacturer of exterior automotive trim parts with number one market ranking in China and growing global significance. cargo-partner provides the vehicle parts manufacturer with a comprehensive logistics solution for the production of 88,000 vehicles per year. Read on to find out how cargo-partner achieves a warehouse accuracy of 99.9% and why every handling step needs to be captured by a scanner.

Minth Group, established in 1992 in China, is a classic hidden champion of the global automotive industry. With over 18,000 employees, the company is a world-leading supplier in design, manufacturing and sales of body structural parts, trims and decorative parts of passenger vehicles. In addition to 30 factories throughout China, the company also operates production facilities in the USA, Thailand, and Mexico as well as Sales and Design Centers at major automotive hubs such as Tokyo, Munich and Detroit.

Comprehensive automotive logistics package

Minth has been using the cargo-partner logistics center in Dunajska Streda, Slovakia since 2013 to optimize its logistics processes with its end customers in Central and Eastern Europe. The cooperation with cargo-partner began with simple cross-docking services and quickly grew to encompass more and more specific automotive logistics solutions. In 2019, the two companies set up an end-to-end logistics process for a customer of Minth at the cargo-partner Automotive Competence Center in Dunajska Streda. Today, cargo-partner provides a comprehensive automotive logistics service package for Minth, covering the entire process from inbound to outbound logistics. In addition to the storage and preparation of goods according to call-offs by OEMs, the provided services include specific packaging, repacking, kitting, VDA labeling (compliant with the norms of the German Association of the Automotive Industry), WMS scanning and monitoring, T1 customs handling, invoicing, and personalized reports. To ensure smooth processes, cargo-partner works with the OEM’s own manuals and WebEDI systems.

Commitment to precision: 99.9% warehouse accuracy

cargo-partner supports Minth in the production of more than 88,000 cars per year, handling approximately 120 different stock keeping units (SKUs). Since the leading automotive supplier needs to ensure reliability for its customers, Minth expects full transparency and continuous process improvements. The highest precision is necessary to ensure smooth production flows – not even a single piece can be out of place. From the start, cargo-partner made a commitment to maintain a warehouse accuracy of at least 99.9%.

“Our customers expect very high reliability in our services, so we need a partner who can ensure the highest accuracy and transparency in all processes. With cargo-partner, we have achieved a maximum performance rate while maintaining optimal cost control.”

The Minth Logistics Department HQ appreciates the effective collaboration.

Close monitoring and streamlined outbound processes

The logistics provider closely monitors current inventory levels and compares them to the advance shipping notices (ASN) received from Minth as well as the daily call-offs by Minth’s customers. As soon as the goods arrive in the cargo-partner warehouse, they are relabeled to reflect the customer’s item numbers and fulfill their sorting requirements. To streamline outbound processes, cargo-partner has set up numerous EDI connections with Minth’s end customers, so that ASNs are automatically transmitted from cargo-partner to the OEMs (original equipment manufacturers). This way, all parties are up to date about expected deliveries. Finally, cargo-partner prepares the goods according to the call-offs by OEMs just in time for pickup.

Personal consultation and detailed reports

To ensure full transparency and end-to-end documentation, goods are scanned at every single handling step: whether they’re being sorted into the shelf, going through quality checking, being repackaged or sent on their way to an outbound delivery. Personalized reports give Minth an easy overview over current stocks, inbound and outbound flows as well as outstanding pro-forma invoices. Based on cargo-partner’s expertise in supply chain management, the logistics provider can support Minth with detailed consultation to achieve a continuous optimization of processes. Thanks to the long-standing industry expertise and tailor-made service provided by cargo-partner’s Automotive Competence Center, Minth benefits from significant advantages in regard to performance and cost optimization.

We support every aspect of your automotive supply chain, from inbound logistics and aftermarket parts distribution up to vehicle transport. VDA data integration ensures fast and efficient handling. We offer flexible solutions for just-in-time (JIT) and just-in-sequence (JIS) delivery, spare parts services, freight optimization, dangerous goods transports, various packaging options and dedicated automotive warehouses with a range of value added services. Our highly trained teams provide speed and 24/7 service for time-sensitive automotive shipments.

“Our industry will remain extremely volatile”

- Interviews

Hapag Lloyd is known as the fifth largest container carrier worldwide. We invited CEO Rolf Habben Jansen to talk to us about sea freight, acquisition plans, the new silk road and ice hockey.

More information

Efficient spare parts logistics for ENGEL

- Success Stories

The international machine manufacturer has centralized its worldwide spare parts supply. But parts are not just parts – some demand special handling under special conditions.

More information

Welcome to the Container Class

- Facts

You think you’ve seen everything – from luxury liners with 5-star suites to hideaways far away from mainstream tourism? But have you ever considered a trip in the ‘Container Class’?

More information

Simply stunning: 1,000 hippos, 1.5 olympic pools and 9 Burj Khalifas

- Insights

cargo-partner is strongly investing into the expansion of its worldwide logistics capacities and opened its new all-timber warehouse in June.

More information

Have you heard of Singles Day?

- Facts

Black Friday and Cyber Monday are known as shopping extravaganzas and consumer-friendly battles for the lowest prices. Singles Day, however, eclipses these events by far.

More information